Embedded Smart Power Electronics (5ESPE)Detailed program - Scientific training units

Training units list

The training is cut into 5 scientific training units (Unité de formation : UF) and a core curriculum :

1- Electronic architecture for the energy

2- Software and embedded automatic for the energy

3- Technology, manufacturing and industrialization of electronic systems

4- Electrical and electronic management for the electric vehicle

5- Interdisciplinary project: Realization of an intelligent photovoltaic production manager

|

Embedded Smart Power Electronics | |

|

UF1- Electronic architecture for the energy |

UF2- Software and embedded automatic for the energy |

|

UF3 - Technology, manufacturing and industrialization of electronic systems |

UF4 - Electrical and electronic management for the electric vehicle |

|

UF5 - Interdisciplinary project: Realization of an intelligent photovoltaic production manager | |

|

Human sciences training common to all the 5th year students (75h) | |

Electronic architecture for the energy Training unit (I5AEEEE11)

This UF aims to know how to determine, size and realize the electronic architecture of an embedded system, select the components, under energy constraints: battery constraint, autonomy, energy sources availability… The UF approaches therefore, the issues of architecture of electric power converters, installation of charging systems and battery management, and architecture with multiple energy sources (intermittent renewable energy). The measurement of physical quantities (current, voltage, temperature, angle ...) is essential in a chain of energy conversion or control of an electromechanical actuator. The UF also discusses different sensor technologies and associated instrumentation electronics

Targeted skills:

- Chose an electronic architecture to increase energy autonomy.

- Dimensioning the electronics of an energy conversion chain

- Choose electrical energy storage solutions and know the associated constraints

- Manage charge / discharge of a battery, balancing

- Implement an ambient energy recovery solution to make embedded systems energy self-sufficient, and get them started with a small amount of energy

- Realise a HW/SW co-design

UF contents:

- Reconfigurable electronic architecture of energy converters for embedded systems: course describing the various energy conversion solution (linear regulator, switching power supply), the associated constraints and the dimensioning. The teaching is backed by a switching power supply sizing practical work, mixing design by simulation and prototyping.

- Sensors and versatile instrumentation: the course broaches the principle of operation of the different types of sensors (optronics, thermal, mechanical, acoustic...), as well as the implementation of these sensors, and the way of processing the signals from these sensors. This teaching is based on a practical work, the aim of which is to manipulate different sensors (an accelerometer, a photosensitive sensor, and a pyroelectric presence detection sensor), then to design and test an electronic architecture to shape signals from sensors.

- Electric energy management and recapture: this teaching concerns the implementation of ambient energy recovery solutions (photovoltaic, piezoelectric, thermoelectric, and electromechanical) to make energy autonomous systems. As the recovered energy has to be stored, this teaching is coupled with that of Electrical Energy Storage Management. Teaching is carried out in the form of project learning, the objective of which is the specification, implementation and validation of an energy recovery solution (chosen by the students), the associated conversion, storage (super capacitor or battery) and its management, the output regulator and chain protection elements. This energy recovery and storage chain will be used to power an autonomous communicating node of energy, capable of starting under a low energy level.

Software and embedded automatic for the energy Training unit (I5AELA1)

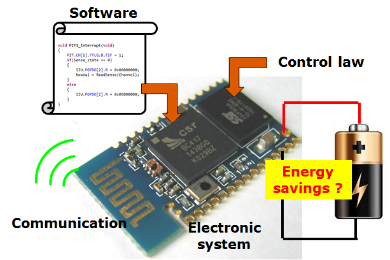

Improving the energy efficiency of electronic systems also requires adequate controls and algorithms to limit the activation of available resources of programmable components. Modelling energy conversion systems is a necessity for the study of their stability, dynamic performance and the elaboration of their control law. This task is not trivial due to their non-linear behaviour (switching speed) and therefore requires adapted techniques. This UF deals with controls for static energy converters and for motors, in order to optimize the energy efficiency of these systems. The UF also addresses algorithmic aspects for low-energy programming, where concepts are implemented through a wireless communication application.

Targeted skills :

- Static converter modelling (linearization around the equilibrium point, non-linear models, switched models, etc.)

- Synthesize and perform controls for static converters of electrical energy (linear control, non-linear control)

- Synthesize and control an electromechanical actuator (vector control)

- Select a wireless communication to increase the energetic autonomy.

- Conceive an embedded software permitting to reduce the energetic consumption of the Programmable platform.

UF contents :

- Control of the static converters: this teaching aims to determine by modelling the static converter control allowing to guarantee the stability of the output voltage depending on the load to be supplied. This teaching is composed a 12.5h course, and two sessions of practical works which aim to model an energy converter.

- Low energy programming for IoT: this teaching aims to give technics allowing to optimize and measure the energy consumption of a programmable platform, playing on the embedded software. The teaching is in the form of two courses on the algorithmic techniques presentation and consumption metrology, followed by 5 sessions of practical work to implement them.

- Energy characterization of an IoT module: Implementation in a microcontroller low energy protocols of information transfer and embedded instrumentation of energy consumption. Several wireless network technologies are available (3G, 4G, 5G, Lora, SigFox, Bluetooth Low Energy). The teaching is in the form of 6 course sessions presenting the typical electronic architectures of the radio nodes and the principles of operation of low energy radio protocols, followed by a practical work.

Technology, manufacturing and industrialization of electronic systems training unit (I5AETE11)

This UF broaches integration aspects, characterisation and electronic systems certification. The students treat the different manufacturing and assembly technologies of electronic systems, addressing the tools of specification and industrial design (PCB routing tool). In addition, the aspects of the design methods and the standards / conformities for the economic placing of an electronic product are addressed. Since power components are subject to high stress and thermal stress, reliability and robustness issues are also addressed. Finally, characterization aspects of different energy-related performances in electronic systems are covered: impedance matching for optimal power transfer to an antenna, EMC and ESD characterization, energy consumption measurement.

This UF is deliberately based on an industrial approach and is carried out around the design of a prototype electronic card in an industrial workshop and its characterization.

Targeted skills :

- Incorporate electronic systems

- Conceive a circuit board under integration, energy, EMC, thermal constraints ... Integrate an electronic system

- Reliability and robustness of the new power components

- Measure the performance of an electronic system (energy consumption, efficiency, EMC, impedance matching)

- Specify and realise the electronic systems certification process

UF Contents :

- Industrialisation and qualification: In this teaching, the students learn how to write the specification of industrialization of an embedded system (BOM, AMDEC, BTF, traceability, component supply), the processes of compliance with the various directives and standards associated with electronic systems (NF 93-713, RTTE, DBT, RoHS, WEEE), to set up a quality monitoring process (ISO17025) as well as the estimation of the reliability of assemblies (FIDES standard).

- Printed circuit board manufacture and assembly the teaching deals with the process of designing and manufacturing printed circuit boards. Students learn how the various technological classes of a printed circuit (rigid, flexible, hybrid PCB) are defined, how to route a printed circuit from the point of view of constraints in line with the aspects of heat dissipation, signal integrity and EMC. They learn and implement the different types of board mounting (merge, single / double, type of finish). This teaching is backed by a stage of manufacturing a printed circuit in an industrial workshop.

- Reliability/Robustness of new power components:

- High performing packaging and cooling:

- Adaptation of antennas: in this teaching, students learn the fundamentals to optimize the transfer of power to an antenna. Tools for scaling and validating impedance matching networks are also introduced and implemented.

- EMC and ESD Characterization of an Embedded System: In this hands-on teaching, students implement standard EMC and electrostatic discharge tests on electronic radio (transceiver) and power (switching power supply) boards.The purpose of this teaching is not only to become familiar with this type of testing, the associated hardware and their typical configurations, but also to evaluate and analyse the influence of design choices (components, placement & routing) on the EMC.

- Energy characterization of an autonomous embedded system:

Electrical and electronic management for the electric vehicle training unit (I5AEGE11)

This teaching focuses on the transport electrification (automobile, aircraft, scooter, Segway…) and in particular the electronic architecture of the control chains of the electric actuators.Guaranteeing optimum energy efficiency, but also the robustness of the system and the operational safety require a wide know-how in electronics and hardware computing.

This teaching is centred around a design office to implement the electronic architecture typical of an electric vehicle’s traction chain (synchronous motor with permanent magnets, inverter, double-core microcontroller, networking on multiplexed buses, monitoring components), using industrial components and taking the constraints of the automotive sector (integration, safety, performance, embedded diagnosis, EMC). The teaching is done in partnership with the company NXP.

Trageted skills :

- Knowledge of electric vehicle actuators and advanced controls

- Choosing the electronic architecture of electromechanical actuator control chains

- Components and integrated technologies for electric vehicles

- Size and control of an electromechanical actuator to optimize energy efficiency

- Dimensioning electronic architecture and embedded software to ensure safe operation of the electromechanical actuator control chain

UF Contents :

- Engine and command for electric vehicles: this teaching present different type of electric engines, their architecture and constraints and the way that we control them. The teaching mainly focuses on the permanent-magnet synchronous and the asynchronous engine. One of this teaching objectives is to determine the engine command use during the design office.

- Sizing of an energy converter for transport: our school geographic location, with the presence of the aeronautics industries and particularly with the Aerospace Valley hub forces us to talk about electric actuation in airplanes for example. These actuators are characterized by particular mission profiles, for example with a very low duty cycle, or with application of a quasi-continuous resistive torque. With problems of containment and cooling. Moreover, in this field, we have skills at the INSA, external intervention on the evolution of electronic architectures, actuators, batteries in view of an increasing electrification of Aircraft.

- Safety automobile introduction: the electronic equipment for automobiles associated to the traction chains must answer to strict safety requirements. In the automobile sector, they must comply with the highest level of ISO26262 rated ASIL-D. The components choice, the electronic and software architecture must be specified and conceived to answer to this fundamental requirement. During this teaching, a quick introduction to the functioning safety requirements in the automobile is done, explaining how it impacts the electronic equipment architecture. A failure mode analysis of the different traction chain components is done in order to identify the material and software solutions allowing to guarantee the driver and passengers’ security. These solutions will be set up in the design office. The concepts broached during this class are transposable to other industrial sectors such as aeronautics.

- Introduction to automobile components: the automobile equipment use highly integrated and configurable components to reduce manufacturing costs, reduce energy consumption, and ensure robustness and safe operation.This teaching is composed of several interventions made by industrial stakeholders, presenting the various technologies embedded in an electric vehicle. The interventions focus particularly on the components implemented during the design office (double-core lockstep microcontroller, gate driver, power SBC, multiplexed bus drivers for the automobile).

- Electronic automobile BE – Main inverter: the design office’s aim is to set up the main electronic equipment of the traction chain, named main inverter, that is to say the inverter that drives the engine of an electric vehicle. This will be made from automotive components provided by NXP, a partner of this design office. The design office runs through a project realized by 12-student teams. The first part of the design office is dedicated to the drafting of a detailed specification of the hardware and software architecture of the system from a set of specifications. This specification integrates the theoretical study of the engine carried out in the teaching of Actuators for the electric vehicle, as well as the safety analysis made in the teaching Introduction safety automobile.The second part is devoted to the realization of embedded software and modular tests, to demonstrate the operation of the system in line with the specifications. The design office will be evaluated through the specification and completion reports, as well as by a final defence.

Interdisciplinary project training unit: realization of an intelligent photovoltaic production manager (I5AEPR11)

In this UF, students work in teams in great autonomy on transversal projects addressing most of the concepts covered in other UF, these projects are related to the hardware, software design and development of control laws for an intelligent renewable energy manager for a micro-grid. Each team will be in charge of the specification, the development and validation of a manager's brick. These teachings are part of smart electric distribution network theme (smart grid) and renewable energies. Each team realization will be validated on the GEID’s photovoltaic platform and will be highlighted by a final viva with a poster presentation and the end of the semester. This UF is coupled with English teaching.

Targeted skills :

- Introduction to smart grids/ microgrids

- Chose a converter structure

- Chose and electric energy storage structure

- Size the converter commands

- Make an embedded software

- Make the wireless communication layer between sensors and energy managers

UF Contents :

- Introduction to the smart grid networks: project put into perspective by industrial / academic interventions on the theme of electronic architecture for smart-grid, micro-grid, renewable energy, eco-design

- Project: each team will have to specify a manager's brick on the GEID micro grid network. Each team will be accompanied by a teacher – client. Monthly plenary meetings will be planed, during which each team will present the progress of its work in front of an examination board. The project will be asset by the reports the assessment, the presentation in front of the expert jury and the poster’s presentation.

- English: reports preparation, poster presentation and English viva.

Mise à jour le 02/05/2018 A. Boyer